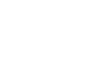

Steel Tee Lintel-1

• Steel grade: Q235B/Q355B

• Dimension: 200X200X6/8/10;250X250X6/8/10

• Surface: HDG, Standard AS/NZS4680

• Length: 1200mm ~5800mm

• Suitable for Australia Market

• FOB Qingdao: USD 900-1000/Ton

• Production Capacity: 600 tons/Month

• Leading time: 20-40 days

• Package: Steel straps bundled

DETAILS

Hot dipped galvanized T bar Traditional T bar

◆ Company Profile

SuperM Steel Galvanized T bar is fully machine welded structural lintel beam manufactured by SuperM Steel using Q235B/Q355B Grade Carbon steel. They are traditional steel sections used in the support of brickwork over large clear openings and are not reliant on composite action , specical to Australia,NZ market. more than 10 years export experiences.Got good reputation from our client.

◆ SuperM Steel HDG traditional T bar features:

1 Fully machine welded structural T-bar.

2 Fully Hot-Dip Galvanised in accordance with AS/NZS4680:2006.

3 Achieves R3 Durability Rating in accordance with AS/NZS2699.3.

4 Compliant with all relevant Australian Building Codes & Australian Standards.

5 Professional manufactory and exporting more than 10 years.

6 Full product warranty.

7 Continuous welding and hole punching as request for easier delivering, loading andunloading

8 Long life and durable

9 Easy installation and cost effective

◆ Processing & Production:

1. prime saw cutting the certain length as order request

2. punching holes at the exactly area according to drawings

3. T Section Assembling according to drawing

4. Auto Submerged Arc continuous welding

5. Auto Straightening with tolerance +/-2mm.

6.surface hot dipped galvanized.

7. packing by steel strips, each bundle 5 pcs

8. container loading

◆ Product Description

200/8mm (v) x 200/8mm (b) | 200/10mm (v) x 200/10mm (b) | 250/10mm (v) x 200/10mm (b) | 250/12mm (v) x 200/10mm (b) |

(25.4kg/m) | (31.4kg/m) | (35.4kg/m) | (39.3kg/m) |

mm | mm | mm | mm |

2700 | 2700 | 5200 | 5200 |

3000 | 3000 | 5400 | 5400 |

3300 | 3300 | 5700 | 5700 |

3600 | 3600 | 6000 | 6000 |

3900 | 3900 | 6300 | 6300 |

4200 | 4200 | ||

4500 | 4500 | ||

4800 | 4800 | ||

5200 | 5200 | ||

5400 | 5400 | ||

5700 | 5700 | ||

6000 | 6000 | ||

6300 | 6300 |

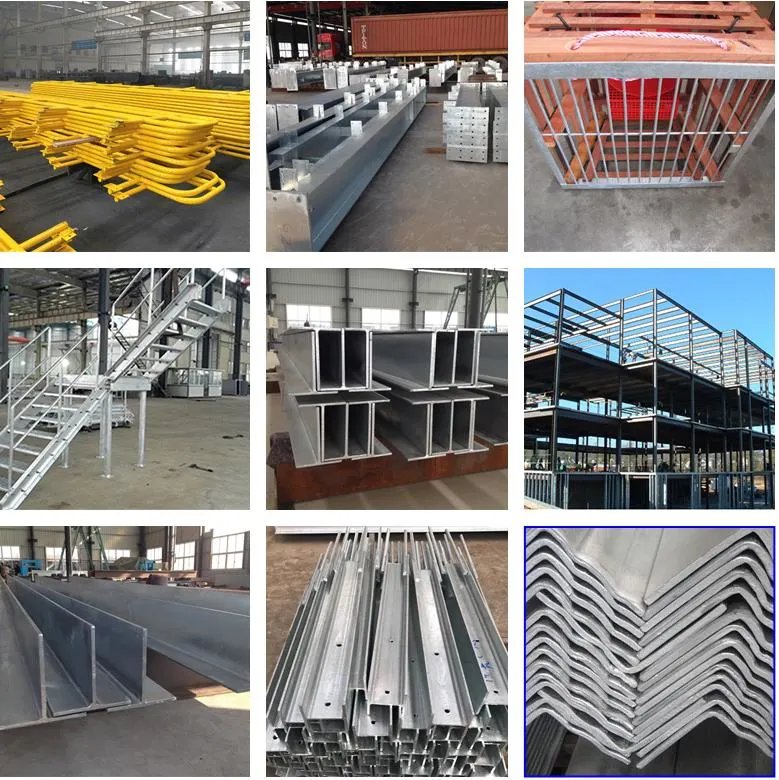

◆ Quality Control

1. QC processing:

1. Every 3 months meeting for Quality Audit to solve the weakness during processing and procedures

2. Every 6 months meeting for employee training.

3. Producing as to the International Steel Structure Standard with ISO 9001 Quality Control System

4. Each project, every 6 months, connecting with clients for feedback and complaints, then improve the quality control actions.

5. Quality inspection report for every process during production. Ensure 100% good quality products.

◆ Company Certificate of us:

◆ Partnership Progress

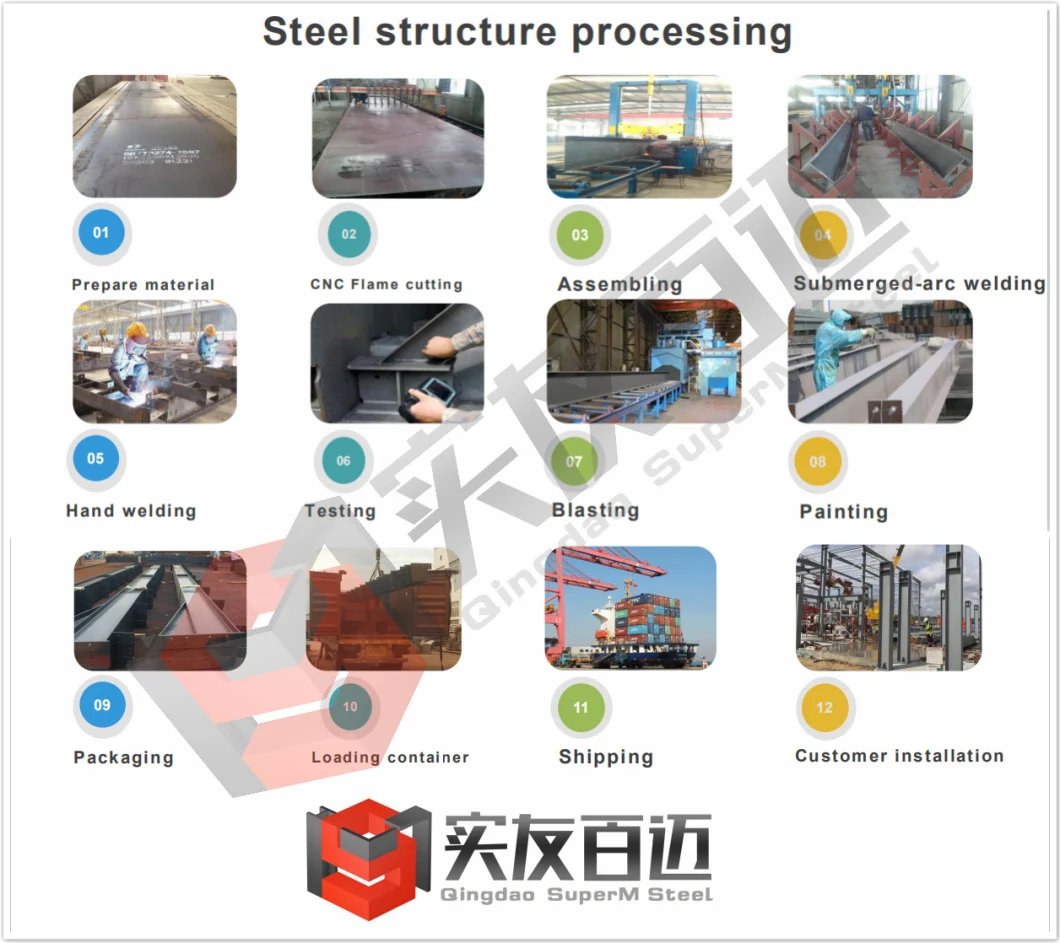

◆ Production Progress

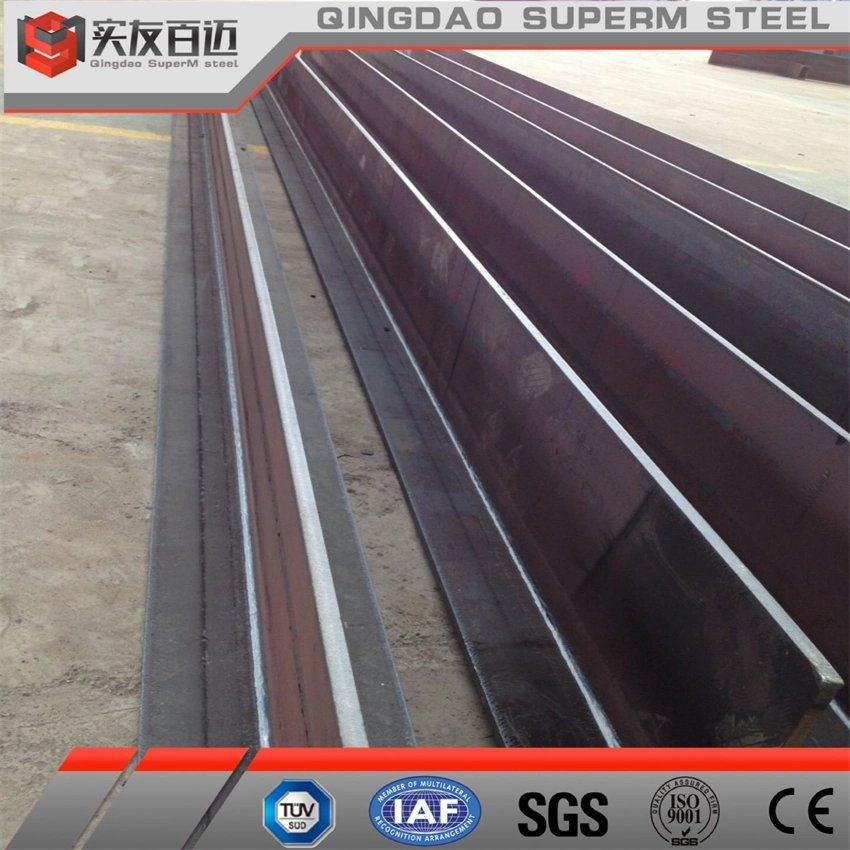

Qingdao SuperM Steel Company design, supply & install steel structure buildings(steel structure workshop, steel structure warehouse buildings, steel structure hangar)

More than 10-year experiences.

1. Prepare Material⇒2. CNC Flame Cutting⇒3. Assembling⇒4. Submerged arc welding⇒5. Hand welding⇒6. Testing⇒7. Shot blasting⇒8. Painting⇒9. Packaging ⇒10. Loading

container⇒11. Shipping⇒12. Customer installation

◆ Packaging & Shipping

◆ Customer Visiting

◆ FAQ

Q:Can you provide product catalog and quotation?

A: It is better if you can provide drawings(PDF or CAD),we will give you complete your drawings offer. or

We can design as the request from you, then proposal.

Q:what is you used drawing format?

A: PDF or DWG as AUTO CAD file

Q:What is the minimun order quantity?

A:No MOQ limited.

Q:What is your packing?

A:Standard export package for container transportation by sea and can be packed as customer's requested.

Q:How long is the delivery time?

A:According to project situation, usually within 30 days after receiving deposit.

Q:What is your payment?

A:T/T , 30-70 or LC at sight.

Q: Do you company offer Guide installation at project site ?

A: Yes, usually we will send you the detailed installation drawing, if you need, we can provide the service of installation, supervision and training by extra. We can send our professional technical engineer to supervise installation on site overseas.

FREE INQUIRY NOW

If you have any questions or needs about the product, please fill in the following form and we will contact you as soon as possible.